There are many types of surface treatments that serve different purposes, each with various factors that make them appropriate for their specific use. I will explain the different types of standard surface treatments to help you become clearer on which one you need.

Firstly, there is anodising. This is a complex process that involves electrically converting an aluminium surface to columnal structure of aluminium oxide. The structure is porous and can be sealed using a variety of chemistries in order to add extra beneficial properties.

Another type of standard surface treatment is plating. Plating is when metal is placed onto the surface of a conductive material. This is done using various methods, such as electroplating or auto-catalytic plating.

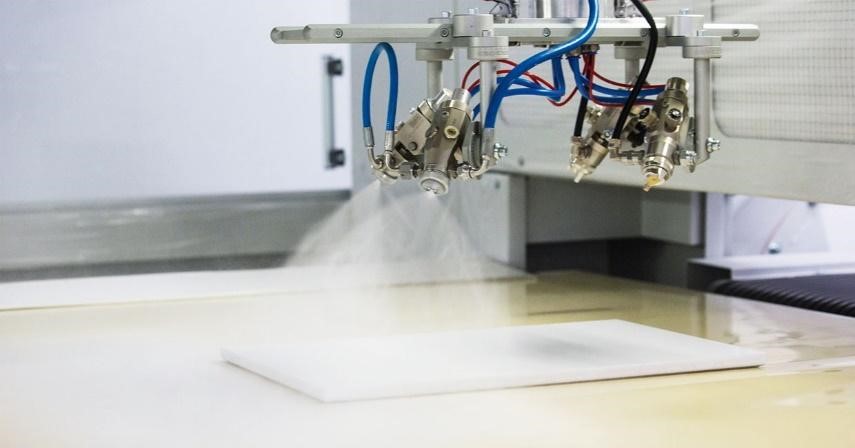

There are also thermal and metal spraying techniques that can coat things such as electric wires in plasma.

Conversion Coating is a surface treatment that is used to prevent the corrosion of aluminium. It is also an ideal surface to paint on, as it improves the bond of the paint to the surface. If coatings and paint are applied to an aluminium surface without any prior surface conversion, the paint may flake off due to poor adhesion.

Dry film lubricant treatments are used to reduce wear and tear, heat generation and galling. There are various types including Fluoropolymer (PTFE, FEP, ECTFE), Graphite based film lubricant, Molybdenum Disulphide (MoS2), and Tungsten Disulphide (WS2).

Lastly, paint is used as a pre-treatment for surfaces with defence qualities making it appropriate for aerospace equipment. There are anti-corrosion coatings, defence paint and aerospace paint.

If you are looking for Surface Treatments, visit the website https://www.poeton.co.uk/standard-treatments.